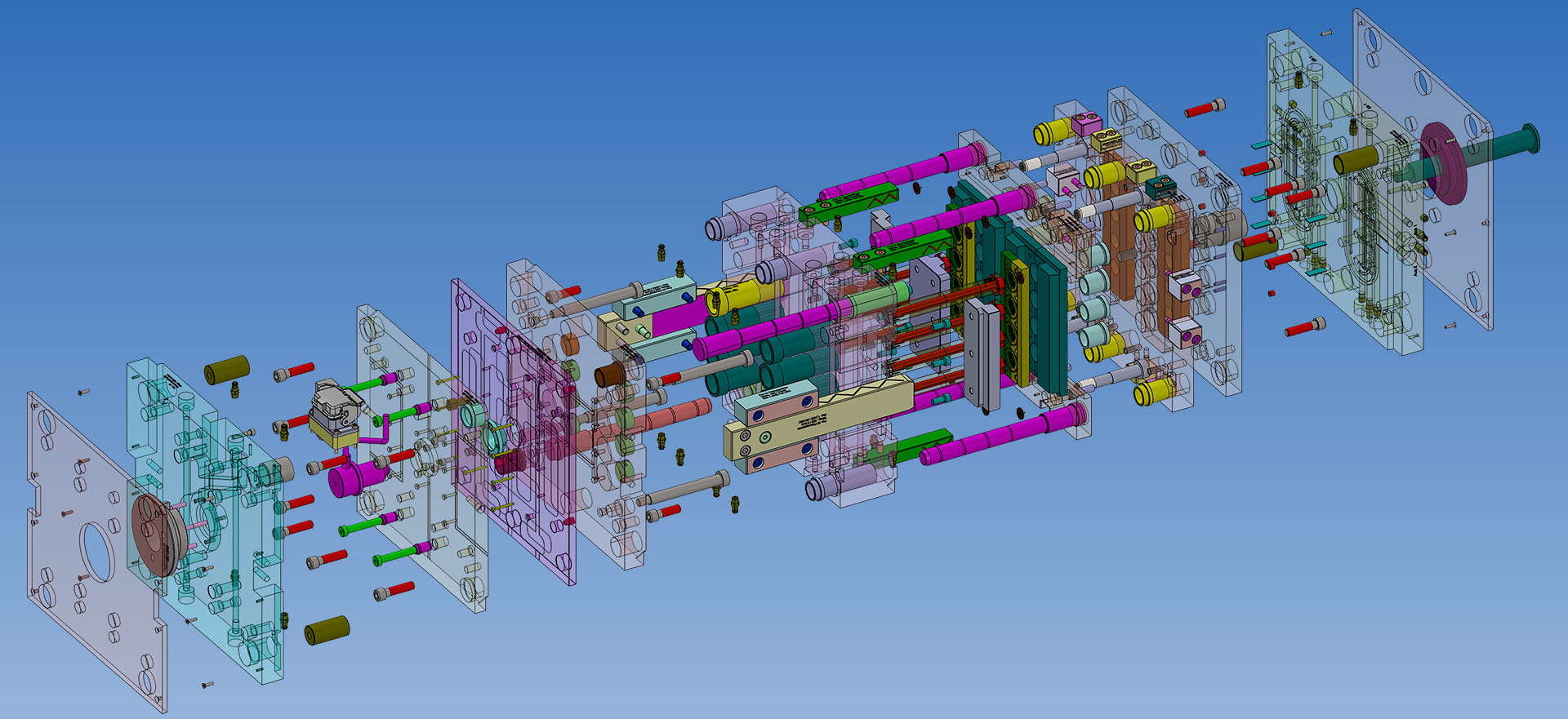

In-house design and toolmaking

With decades of experience, we provide reliable advice on the planning of new tools and ensure that every project is implemented to a high standard of quality.

Thanks to our own metalworking machines, we create the optimal basis for our production. This allows us to implement individual customer requirements in addition to standard parts—including design, prototype construction, 3D printing, and cost-effective tool manufacturing. Direct on-site production allows us to work more efficiently and with fewer errors, enabling us to respond more quickly to your requirements.

Production planning and control

Production planning and control – we think ahead before production begins

We accompany you from the initial idea to market readiness with our experience and development services, combining your vision with design and technical implementation.

From the initial idea to market readiness, we accompany you as an equal partner. Our aim is not only to implement your vision, but to shape it together. We combine design, technical feasibility and production knowledge to ensure that your product is optimally thought out from the outset.

We carefully plan, continuously monitor and flexibly adapt every order – we think things through, examine alternatives and make recommendations that bring real added value. This results in solutions that are not only manufactured, but understood.

Why we offer more than just production:

Holistic development support: We provide advice right from the concept phase to ensure that your idea is implemented efficiently and is ready for the market.

Individual planning & control: Every step is planned and monitored transparently – with a focus on adherence to deadlines and quality.

Partnership approach: We listen, ask questions and work with you to develop innovative solutions.

Time for your vision: We consciously take the time to understand your project and actively contribute our ideas.

Laboratory & Research

As a manufacturer of high-quality markers and applicators, we develop and produce our products directly on site. In our in-house laboratory, we combine state-of-the-art technology with precision craftsmanship to create products that meet the highest standards. Our team not only tests compliance with current guidelines and safety standards, but also checks the functionality, durability and quality of our writing instruments and applicators. We pay attention to every detail – from ink flow control to the ergonomics of use. Innovation is at the heart of what we do: we develop future-oriented and solution-oriented concepts that offer our customers real added value. Through continuous research and close cooperation with our partners, we keep our finger on the pulse and set trends in the industry. With our laboratory at the heart of our product development, we ensure the quality, reliability and performance that our customers worldwide trust.

Production

Plastics processing

We manufacture precision plastic components in our constantly expanding, highly automated machine park – entirely in Germany.

We rely on:

- High level of automation for consistent quality

- Cost efficiency through optimised processes

- Quality improvement using state-of-the-art technology

A wide range of colours according to Pantone colour matching enables individual design according to customer requirements.

Filling and assembly

Our end products (pens or similar applicators) are manufactured on our fully automated German assembly lines. Thanks to our automated assembly and filling systems, we can reliably produce large volumes in a short time. The entire process – from filling and assembly to final functional testing – runs efficiently, smoothly and according to strictly defined standards.

Decoration technology – Precise brand messages on every writing instrument

High-quality screen printing, pad printing and multi-coloured container labels are possible.

On our modern assembly lines, we decorate your products directly during production – quickly, precisely and entirely according to your specifications.

We apply your design securely and permanently to every housing.

We offer you:

High-quality screen printing for large-scale, colour-intensive designs

Pad printing for fine details and curves

Multicoloured container labels for complex motifs and brilliant colour gradients

Abrasion-resistant and durable prints, ideal for frequently used writing instruments

Decoration on fluorescent, transparent and matt surfaces

This results in advertising and branded products that not only look good, but also perform well in everyday use. From small quantities to large series – we implement your CI perfectly.

Packaging and shipping

Packaging technology

Whether blister packs, folding boxes, bags, displays or other forms of packaging – we offer all solutions directly in-house.

Thanks to our long-standing, experienced partner companies, we work hand in hand and together find the most sustainable and efficient packaging options.

Continuous quality monitoring

Our primary goal is to deliver the highest quality and error-free products. That is why we work with a fully integrated quality management system that continuously monitors all relevant development, material and manufacturing parameters. From design and prototype testing to series production, we use defined control points, precise measurement methods and documented test procedures to identify deviations at an early stage and continuously optimise processes. This ensures that every product meets our strict standards – technically mature, reliable and flawless.

Logistik und Versand Just-in-Time

Die bedarfssynchrone Auslieferung erfolgt bei uns Just-in-Time. Der Versand aller Produkte wird gezielt auf unsere Produktionsabläufe abgestimmt, um unseren Kunden besondere Flexibilität und kurze Lieferzeiten zu gewährleisten. Wir arbeiten mit renommierten Logistikanbietern zusammen, die umweltbewusst agieren und die Produkte für unsere Kunden sicher in die ganze Welt verschicken!